Willkommen am Arbeitsbereich für Umwelttechnik!

Wir sind Teil des Instituts für Infrastruktur an der Fakultät für Technische Wissenschaften der größten Forschung- und Bildungseinrichtung in Westösterreich, der Universität Innsbruck.

Wir beschäftigen uns mit umwelttechnischen Fragestellungen (Schutz der Umwelt vor dem Menschen und Schutz des Menschen vor der Umwelt) in Forschung und Lehre. Ein Hauptaugenmerk hierbei liegt auf der Untersuchung regionaler (alpiner) Problemstellungen mit dem Ziel nachhaltige technische Lösungen zu entwickeln.

Lernen Sie unsere Forschungsschwerpunkte kennen:

Abfallbehandlung und Ressourcenmanagement

Über Uns

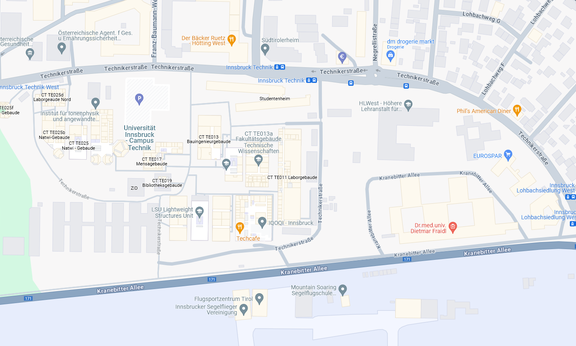

Arbeitsbereich Umwelttechnik

6020 Innsbruck, Austria

Tel:

Fax: +43 512 507 62199

Mail:

GPS: 11°20‘42,66‘‘/47°15‘50,35‘‘

Forschung

Hier finden Sie Informationen zu den Forschungsschwerpunkten am Arbeitsbereich Umwelttechnik.