Latest news

Here you will find all news and information on events relating to our field of work

Courses winter semester 2025/26

The following courses are offered by the Chair of Production Engineering as part of the Bachelor's and Master's degree programme in Mechatronics in the summer semester 2024.

- 850501, VO Production Engineering

- 850503, PR CNC and machining processes

- 850555, VU Materials Science 2 - Specialisation: Factory Organisation

- 850558, VU Industry 4.0

- 800773, VU INNklusion - Development of assistance solutions for people with disabilities in interdisciplinary teams

Further information on our new INNklusion course can also be found on the project's website Homepage!

Courses summer semester 2025

The following courses are offered by the Chair of Production Engineering as part of the Bachelor's and Master's degree programme in Mechatronics in the summer semester 2024.

- 850556, VU Human-Machine Systems

- 850552, VU Production Engineering 2

- 850905, PR CAD

- 800799, VU INNklusion - Development of assistance solutions for people with disabilities in interdisciplinary teams

Further information on our new INNclusion course can also be found at Homepage of the project!

events

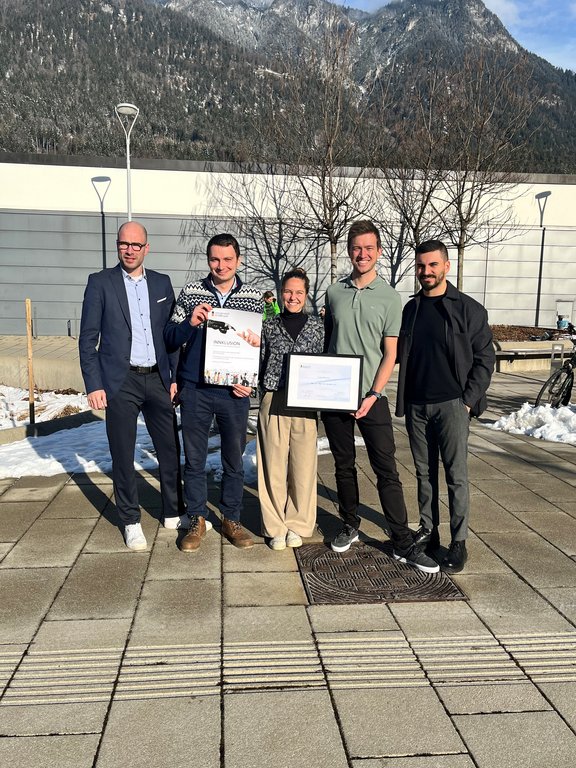

INNklusion receives Inclusion Award 2024

The INNklusion initiative at the University of Innsbruck was awarded the Austrian Inclusion Prize 2024 in the Technology and Digitalisation category. The prize was accepted by Samet Ersoysal, Oliver Ott, Lennart Ralfs and Katharina Schmermbeck on behalf of the entire INNklusion team at a ceremony in the Kursalon Vienna on 26 November 2024.

INNklusion is an initiative of the Chair of Production Engineering at the Department of Mechatronics at the University of Innsbruck, which is headed by Prof. Dr Robert Weidner. It promotes co-operation between students and people with disabilities in order to jointly develop assistance technologies. The programme combines future-oriented teaching and social commitment, with a particular focus on creativity and interdisciplinary cooperation. The aim is to create solutions that enable a barrier-free future and promote the participation of people with disabilities in society.

"This initiative would not be possible without the valuable support of people with disabilities, whose experience and knowledge are indispensable to us, as well as the dedicated collaboration of our students and university staff. This award is a joint success that could only be achieved through the close cooperation of all those involved," says the INNklusion team.

The initiative shows that inclusion is an ongoing process that shapes a barrier-free future through projects and the cooperation of all those involved. Students are currently working on various projects in the winter semester 2024/25, including a tactile model for the Agnes Heller House that helps people with visual impairments to find their way around better, the design of quiet rooms for students and staff with neurodivergences and low-barrier concepts for the USI sports programme to facilitate access to sporting activities. These projects are just a few examples of how INNklusion integrates the needs of people with disabilities into the design of living spaces and everyday technologies.

Further information and videos are available on the Lebenshilfe website at the following link: https://www.lebenshilfe.at/inklusion/inklusionspreis/" and on the Lebenshilfe YouTube channel.

Lebenshilfe Inclusion AwardINCLUSION

Ars Docendi Recognition Award for INNclusion

Our Chair of Production Engineering was awarded a recognition prize as part of the Ars Docendi 2024 award presented by the Federal Ministry of Education, Science and Research on 10 September 2024 in Vienna. Our course "INNklusion - Assistance solutions for people with disabilities" received the recognition in the category "Society- and sustainability-oriented teaching".

In the course, Master's students work together with people with disabilities on an interdisciplinary basis to develop innovative assistance solutions. Previous projects include a concept for reduced-irritation shopping and a cover-up aid for people with mobility impairments. INNklusion not only promotes the active participation of people with disabilities, but also encourages students to tackle socially relevant challenges. The award is a great honour and confirmation of our teaching approach and motivates us greatly to continue developing INNklusion.

A detailed article on the award and general information on INNklusion can be found here:

Participation in the VDI - MGA student competition 2024

This year's VDI - MGA student competition took place from 26 to 28 April at EOS - the world's largest machine manufacturer for additive manufacturing. We from the Chair of Production Engineering took part with two teams as part of the Production Engineering 2 lecture. This year, a total of 13 teams with almost 100 people from various universities gave an impressive demonstration of their skills. This year's theme was "Robotics". The teams developed new and innovative products for various applications, including a business plan and a marketing strategy.

We are very pleased with the success of our students. Our "Pro Play Analytics" team developed a sports trainer that took first place. The jury also recognised a solid business plan and marketing strategy. The jury also praised the documentation, which, according to the judges, "could compete with investor pitches worldwide". Our team "4Paws4Comfort" has developed active, modular prostheses for animals."

We would also like to take this opportunity to thank the hosts (Jette Dietrich, Mariella Breinlinger, Lea Markievicz) and judges (Marc Fette, Linus Tillmann, Bianca Daiminger, Sascha Hartig & Patrick Gerhardt). It was a pleasure to take part and we will gladly return next year.

Vacancies

Chronicle

Launch event Long Night of Research 2024

The kick-off event for the Long Night of Research was held in Vienna on 23 April 2024 . The event began with a press conference attended by high-ranking personalities such as Federal Minister Polaschek (Federal Minister of Education, Science and Research), Federal Minister Gewessler (Federal Minister for Climate Action, Environment, Energy, Mobility, Innovation and Technology) and Federal Minister Kocher (Federal Minister of Labour, Family and Youth).

An outstanding highlight of the launch event was our presentation of the INNklusion initiative by Prof. Dr Robert Weidner, Oliver Ott and Heidi Ulm, representing the team from the Chair of Production Engineering.

The INNklusion initiative is committed to an inclusive future by developing and implementing various assistance solutions together with an existing network of people with disabilities, stakeholders, experts and students. The presentation provided an insight into the project, which aims to create a barrier-free environment and actively involve people with disabilities in the research and innovation process.

Further information on the INNklusion initiative can be found at Project homepage.

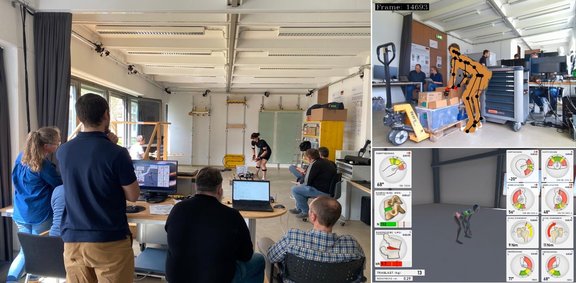

Launch of the ExoExpert project

Cooperation between humans and technology, for example in the world of work, has intensified in recent years. As an approach to supporting human labour, exoskeletons have increasingly emerged as a suitable support technology in industry. Depending on the production scenario, exoskeletons are suitable for supporting workers by either facilitating or supplementing movements or stabilising postures. However, supporting methods or tools for the simulation-based selection and adaptation of exoskeletons only exist for individual aspects to date.

ExoExpert is attempting to close this gap with a novel planning method including a simulation model. Exoskeletons should be able to be better evaluated, selected and customised for industrial application scenarios. This will support the development process of occupational scientists, ergonomists and engineers.

The project is a cooperation between the Chair of Production Systems at Ruhr-Universität Bochum and the Department of Production Engineering at the University of Innsbruck and is funded by the German Research Foundation and the Austrian Science Fund.

Further information on the project can be found at here.

Univ.-Prof. Dr.-Ing. Robert Weidner elected new President of the ÖWGP

At the General Assembly of the ÖWGP on 26 February 2024, Univ.-Prof. Dr.-Ing. Robert Weidner was elected as the new President of the society. Together with Vice President Univ.-Prof. Dipl.-Ing. Dr. mont. Clemens Holzer (Chair of Plastics Processing at Montanuniversität Leoben) and Prof. Dr Sebastian Schlund (Managing Director of Fraunhofer Austria Research GmbH and Head of the Institute of Management Sciences at TU Wien), they will chair the organisation for the next two years.

The ÖWGP was founded on 17 June 2013 based on the model of the German "Wissenschaftliche Gesellschaft für Produktionstechnik (WGP)" and represents the link between universities and industry. The central aim of the ÖWGP is to promote young researchers in the field of production technology.

In addition to the sustainable design of production technology, Prof Weidner also wants to focus on the networking of science and industry, as well as the promotion of young talent.

We wish him every success in his new position!

Das neue Vorsitzteam der ÖWGP (v.l.): Clemens Holzer, Robert Weidner und Sebastian Schlund

Status meeting in the A2P project

As part of the A2P project, we welcomed our project partners to the University of Innsbruck on 22 February 2024. The main focus of the meeting was to discuss the project results to date as well as the upcoming focal points and work content. In particular, the upcoming use case for an adaptive work table at Siemens and the use of robots at Infineon were discussed. The participants were also able to try out the latest developments in the project for adaptive exoskeletons in the PfF laboratory. The project team is looking forward to the work in the coming project year.

Gruppenfoto A2P Statusmeeting

INNklusion - Together for an inclusive future: Successful completion of the course

The new interdisciplinary course"INNklusion - Development of assistance solutions for people with disabilities in interdisciplinary teams" celebrated its successful conclusion on 30 January 2024 with impressive final presentations by the students. This course, which took place for the first time in the winter semester 2023/24, enables students from various disciplines to develop assistance solutions together with people with disabilities.

We are delighted to have completed this socially significant course and would like to thank all participants. The students' intensive collaboration in interdisciplinary teams led to innovative solutions that are directly based on the needs and challenges of the people who need them. At the final event, the projects"Zudeckhilfe","Fotohilfe","Social-Buddy App" and the"Stille Stunde" were presented.

Special thanks go to our esteemed needs organisers Julia Golser, Marianne Hengl, Alina Kühnel and Claudia Mairer as well as our panel of experts, consisting of Bettina Jeschke, Ines Nagiller and Kathrin Schrebe. Their valuable insights, expertise and continuous support throughout the semester contributed significantly to the success of the course.

The course"INNklusion - Development of assistance solutions for people with disabilities in interdisciplinary teams" is not only an opportunity for students to expand their skills in project work and product development, but also an important step towards a more inclusive society. We look forward to offering the course again in the coming summer semester 2024 and working with our students to develop innovative solutions that can sustainably improve the lives of people with disabilities.

Practical CNC and machining processes: Marble run competition

During the 2023/24 winter semester, students learnt the basics and techniques of CNC and machining processes in the course"PR CNC and machining processes". To round off the course, we organised an exciting marble run competition on 29 January 2024. Six groups competed against each other with their self-milled marble runs, with group 6 securing first place thanks to their outstanding time. We would like to congratulate them on this remarkable achievement and are delighted that they have successfully completed the course. A sincere thank you to all students for their hard work and dedicated participation throughout the practical course.

Congratulations on successfully completing the Master's programme

We would like to congratulate our former student assistant and Master's student Gilbert Prokop on successfully completing his Master's degree. In his master's thesis, he focussed on the development and validation of an alternative method for recording muscle activity.

We would like to thank Gilbert for his many years of work and commitment in our working group and wish him all the best for the future.

Best Practice Award from the University of Innsbruck for the INNklusion project

We are delighted that our INNklusion project was honoured with the University of Innsbruck's Best Practice Award last week as part of the Rector's New Year's Reception, Professor Sexl. This recognition is not only an appreciation for our work over the past year, but above all for the collective efforts and initiatives of all the people and supporters involved, as well as associations and societies. Without their open and committed contributions and active participation, the project could not have been realised in its current form.

Background to INNklusion

INNklusion is more than just a project: for us, it is both a great motivation and a pleasure to promote the development of inclusive assistance solutions that can make everyday life easier for people with different disabilities. We are therefore delighted that INNklusion has now also become a permanent part of our teaching and that of the University of Innsbruck.

Focus on participation and collaboration

The success of INNklusion is based on participation and joint dialogue. In close cooperation with people with disabilities, students from a wide range of disciplines, clubs and associations, we design assistance solutions that can contribute to a more accessible and self-determined everyday life. Through creativity, innovation and, above all, empathy, we create solutions that meet the diverse needs of our users. It is therefore not only the development of solutions themselves that is special to us, but above all the platform and the network that enable a valuable exchange with kind and open-minded people and sensitise people to the discrimination and barriers faced by people with disabilities.

Solutions from INNklusion

A wide variety of solutions have already been developed as part of INNklusion. One example is the development of a communication tool that enables people with locked-in syndrome to signal their needs to a carer by minimally moving their little finger. A second example is the development of a concept for the "quiet hour" in retail, which provides measures to counteract the sensory overload in supermarkets and thus improve the shopping experience of people on the autism spectrum, for example. Both projects are the result of the work of students and experts with disabilities, who worked together for six months to collect ideas and develop concepts.

Thanks to our partners and the community

The award is not only due to us, but also to our partners and the committed community, who have enriched us with their experience and perspectives. In particular, we would like to thank the constant support and encouragement of the Rector, the Vice Rectors, the Deans of Studies, the Förderkreis 1669 and the Public Relations Office of the University of Innsbruck. We would like to thank Mrs Bettina Jeschke and our committed participants with disabilities for their sincere feedback and active participation in the project. Together, we are shaping a more inclusive future and providing impetus for the development of assistive technologies.

The Best Practice Award is not only an honour for us, but also an incentive to continue our efforts for a more inclusive future. We look forward to setting further milestones towards inclusion together with our growing community. We cordially invite you to become a part of our community Website INNklusion.

Your team

INNklusion of the Chair of Production Engineering

Gruppenbild des Teams INNklusion.

Autumn conference of the Austrian Scientific Society for Production Engineering (ÖWGP)

The autumn conference of the Austrian Scientific Society for Production Engineering (ÖWGP) took place this year on 10 October 2023 at the University of Innsbruck. We are delighted to have hosted the event as the Chair of Production Engineering (Prof. Robert Weidner) at the Department of Mechatronics.

The ÖWGP promotes co-operation between scientific institutes, social and political associations and industry and pursues the objective of promoting scientific research in the field of production technology through various activities. In addition, the ÖWGP provides answers to the questions of which products in which future organisational forms and with which new production processes will determine value creation in Austria and Europe in the medium and long term. It sees itself as an independent technology platform characterised by interdisciplinarity, international orientation and research-led teaching at universities.

Gruppenbild der Teilnehmer der ÖWGP Herbsttagung 2023.

Conference "Superpowers through exoskeletons"

On 1 July 2023, the event "Superpowers through exoskeletons" took place on the premises of the University of Innsbruck in cooperation with Standortagentur Tirol and Atlanto GmbH. In a combination of lectures and panel discussions, experts from business, industry and science informed the audience about the state of the art, areas of application and possibilities of exoskeletons.

Robert Weidner opened the symposium with the keynote speech "Individual and context-specific support through exoskeletons", in which he emphasised the great potential of exoskeletons to provide support in various areas of life. Other topics at the event included the use of exoskeletons in rehabilitation and as part of workplace design.

The event concluded with an exciting panel discussion with Robert Weidner, Margit Gföhler (Vienna University of Technology), Jasmin Plank (Sportswoman of the Year and World Cup winner in para-climbing) and Markus Knabl (transport and logistics company Gebrüder Weiss), in which the physical limitations and opportunities of exoskeletons were discussed.

Afterwards, the guests were able to experience the use of different models of exoskeletons up close and try them out for themselves.

Further details about the event can be found at here.

INNKlusion - Developing assistance solutions for people with disabilities in interdisciplinary teams

We are very pleased to be able to offer a new course to promote the interdisciplinary and generic skills of our students at the start of the new winter semester 2023/24. We are building on the great support and positive experiences from the INNKlusion project as part of the CAD internship in the summer semester. Together with interdisciplinary Master's students from the University of Innsbruck, people with disabilities and other experts, we will develop assistance solutions for everyday life and thus make a significant contribution to the inclusion of people in everyday life. (contribution attached)

Launch of the "INNKlusion" project as part of the CAD internship programme

Together with the institutions of the Disability Advisory Council of the City of Innsbruck and with the support of the University of Innsbruck, we are launching the "INNKlusion" project. As part of the CAD internship, we will set up teams of experts who will work together to develop assistance solutions for the inclusion of people in everyday life. The aim is to develop new everyday aids using modern technologies such as 3D printing by people with disabilities, mechatronics students and other experts. The project will take place in April 2023 and May 2023.

Congratulations on successfully completing the Master's programme

We would like to congratulate our former student assistant and Master's student Johannes Schütz on successfully completing his Master's degree. In his master's thesis, he focussed on the development and validation of an ergonomics assessment method that works using the sensors built into the exoskeleton.

A warm welcome to our new Bachelor students

A warm welcome to the many young and motivated junior scientists who will be supporting our research on issues relating to the future of work and research into technical systems for physical relief during physical tasks, such as exoskeletons.

We are very pleased about your great interest and are excited to see what results we can work on together as part of your final thesis this summer semester.

Start of the 2023 summer semester

We are starting another semester and are looking forward to accompanying numerous students on their careers this year. The following courses will be offered as part of the Bachelor's and Master's degree programme in Mechatronics by our Chair of Production Engineering in the summer semester 2023.

- 850001, SE Seminar with Bachelor thesis

- 850502, PR CAD

- 850552, VU Production Engineering 2

- 850555, VU Materials Science 2 - Specialisation: Factory Organisation

The courses are supervised by Professor Robert Sebastian Weidner and the research assistants of the chair.

Congratulations to Dr Niclas Hoffmann on passing his doctoral examination

Prof Robert Weidner, Prof Verena Nitsch, Dr Niclas Hoffmann, Prof Manfred Kleidorfer (from left to right)

The Chair of Production Engineering (PfF) congratulates Dr Niclas Hoffmann on passing his doctoral examination on 28 November 2022 with the title "A contribution to the design, evaluation and implementation of industrial exoskeletons". In his dissertation, which was awarded the Doctoral Prize 2022 by the Austrian Scientific Society for Production Engineering (ÖWGP), Mr Hoffmann addressed various issues relating to the development and application of industrial exoskeletons as human-centred support systems. Special thanks go to Prof. Nitsch (RWTH Aachen University, Institute of Ergonomics) for her second opinion and Prof. Kleidorfer for chairing the examination.

Award of the ÖWGP Doctorate Prize 2022 to Mr Niclas Hoffmann

The Austrian Scientific Society for Production Engineering (ÖWGP) honoured Niclas Hoffmann with first prize for his dissertation entitled "A contribution to the design, evaluation and implementation of industrial exoskeletons" at its autumn conference on 17.10.2022 at the Pilot Factory Industry 4.0 at TU Wien. Mr Hoffmann wrote his cumulative dissertation in the Production Engineering working group headed by Prof. Dr Robert Weidner at the Department of Mechatronics of the Faculty of Engineering at the University of Innsbruck.

As part of his work, Mr Hoffmann made a multi-layered contribution to the development and application of industrial exoskeletons on a methodological, theoretical-conceptual and technological level. In addition to methodological approaches as a basis for the design, evaluation and implementation of industrial exoskeletons, novel and forward-looking approaches for system and measurement technology were prototypically realised and validated in laboratory studies. In addition, a frequency-based systematic study on applied development methods and a reconfigurable test course were used to initiate future paths to standardised system evaluation.

The ÖWGP is an association of Austrian production engineering at the supporting institutions TU Vienna, TU Graz, MU Leoben, JKU Linz and the University of Innsbruck. The ÖWGP doctoral prize is awarded annually and is sponsored by the Federal Ministry for Climate Protection, Environment, Energy, Mobility, Innovation and Technology.

On behalf of the ÖWGP, Univ.-Prof. Dr. mont. Jürgen Stampfl (TU Vienna) congratulated Mr Niclas Hoffmann on winning first prize for his dissertation in the field of industrial exoskeletons.

Autumn Conference of the Scientific Society for Assembly, Handling and Industrial Robotics (WG MHI e.V.) on 28 and 29 September 2022 at the University of Innsbruck

The autumn conference of the Wissenschaftliche Gesellschaft für Montage, Handhabung und Industrierobotik e. V. took place at the University of Innsbruck this year. It was hosted by the Chair of Production Engineering (Prof Robert Weidner) at the Department of Mechatronics. In the course of the conference, a laboratory tour of our professorship took place. We are delighted with the positive feedback and would therefore like to thank all participating professors.

The MHI e.V. is a network of leading university professors from German-speaking countries who are successfully involved in both basic and applied research in assembly, handling and industrial robotics. The association was founded in spring 2012 with the aim of optimising teaching and research in the field of assembly, handling and industrial robotics and making it more efficient through cooperation and continuous communication between the members. You can find more information about the WG MHI e.V. at WG MHI e.V.

Tyrolean company run 2022

The Tyrolean company run is one of the largest business runs in Austria and has been held in Innsbruck every September since 2002. Every year, around 5,000 people take part in the evening run through the provincial capital. The athletes took part in the Corporate Challenge on Saturday 17 September 2022 in teams of three. They ran a 5.8-kilometre course that ran along the River Inn and around the Hofgarten. Participants in the walking category had to cover a distance of four kilometres. The Chair of Production Engineering took part in the event with three teams and was able to secure a sensational 4th place out of a total of 329 teams in the mixed competition.

Participation in the 7th MHI Colloquium in Karlsruhe

On 20 and 21 July 2022, the 7th Technical Colloquium of the Scientific Society for Assembly, Handling and Industrial Robotics (MHI) took place in Karlsruhe. Lennart Ralfs and Samuel Villotti (both for Innsbruck) and Max Herrmann (for Hamburg) represented the joint working group as doctoral students. They each presented their conference papers on study-based evaluation and the simulation- and control-based development of exoskeletons. Current and future-oriented research topics relating to robotics and automation were also discussed at the conference.

Summer party at the University of Innsbruck

On Wednesday, 6 July 2022, the University of Innsbruck's staff party took place for the first time in a long time. With beautiful weather, live music and excellent catering, teams were able to compete in the LFU Just for Fun skills competition. The focus was on humour, spontaneity and the joy of interdisciplinary cooperation. The Chair of Production Engineering took a sensational first and third place with two teams and is now looking forward to a joint team breakfast and participation in a sports course in the coming semester.

Automatica 2022 - Successful presentation of current research

As a co-exhibitor of the Scientific Society for Assembly, Handling and Industrial Robotics, the Chair of Production Engineering presented the latest research results at Automatica 2022. From 21 to 24 June 2022, numerous visitors to the world's leading trade fair for intelligent automation and robotics took the opportunity to experience our exoskeletons up close. Interested parties were able to experience the support on their own bodies in industry-related tasks and at the same time follow the innovative approach to dynamic and integrated ergonomic evaluation using exoskeletons on the monitor. We look back on exciting discussions, lively dialogues and are delighted with the new contacts we made.

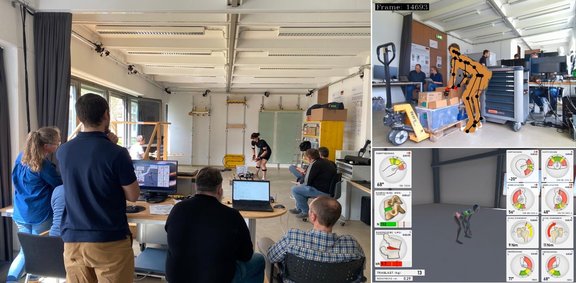

Hands-on ergonomics in the exoATwork module "Practical implementation project"

The participants of the Exoskeletons for Manual Workstations innovation camp met on 26 and 27 April and 24 and 25 May in the movement laboratory of the Chair of Production Engineering at the University of Innsbruck to learn about various ergonomics and workplace assessment methods in theory and practice in a two-day seminar.

In addition to an introduction to the most common overload injuries and an analysis of the biomechanical risk factors, various assessment and measurement methods were presented and applied in order to quantify the loads that occur. Two different work processes were simulated in the laboratory with the focus on modelling a wide range of different manual activities. While two members of our working group "worked hard", the seminar participants were able to literally look under the workers' skin and observe the stresses that occur during work using various sensor and camera-based measurement systems.

As experts for the work processes in the respective companies, the participants will be presented with a tool of assessment methods and procedures. Depending on the boundary conditions and circumstances, they will be able to decide which methods are most suitable in the respective context in order to be able to assess the stresses at the workplaces and (if necessary) carry out the optimisation based on this - which they will also deal with intensively in the following units of exoATwork.

Further information on the FFG-funded exoATwork project can be found at Website Innovation Camp Exoskeletons for manual workstations (exoATwork).

6th Vienna Ergonomics Forum - Lecture on individualised support with exoskeletons

The Austrian Working Society for Ergonomics hosted the 6th Vienna Ergonomics Forum on Tuesday, 21 June 2022. The topic of musculoskeletal disorders (MSDs) in the new world of work and the use of new technologies to prevent MSDs was addressed in various specialist presentations. The Chair of Production Engineering addressed various approaches, distinguishing features and experiences in individual support with exoskeletons and gave participants the opportunity to gain their own experience with a targeted selection of industrial exoskeletons.

Exhibitor stand on the topic of exoskeletons at Automatica 2022

As the Chair of Production Engineering, we will be presenting our latest research results as a co-exhibitor of the Scientific Society for Assembly, Handling and Industrial Robotics (MHI) at Automatica. The world's leading trade fair for intelligent automation and robotics will take place this year from 21 - 24 June 2022 in Munich.

We are delighted to be part of this cross-sector meeting of industry, research and politics. The focus of the Chair of Production Engineering's stand will be the presentation of an innovative approach to dynamic and integrated ergonomics assessment using exoskeletons, which will also be available as exhibits for test use by visitors to the stand.

If you are interested, please contact us in advance of the trade fair: fertigungstechnik@uibk.ac.at

During the trade fair itself, you will find us in Hall A4 at Stand 210 - we look forward to seeing you there.

Samet Ersoysal starts as a university assistant at the professorship

We warmly welcome Dipl.-Ing. Samet Ersoysal as a new university assistant to our team. Mr Ersoysal has already been working at the Chair of Production Engineering as a student assistant since 2019 and will be researching the development of adaptive interfaces for industrial exoskeletons as part of his PhD studies.

Exhibitor at the BGHW's annual prevention conference

The annual prevention conference of the Berufsgenossenschaft Handel und Warenlogistik (BGHW) took place in Kassel from 10-12 May 2022. Lennart Ralfs and Matthias Höfer were invited as external guests for the Chair of Production Engineering and hosted a stand as part of a marketplace on the current research topic of exoskeletons. They reported on the results and experiences of the Exo@Work research project and also offered visitors to the stand the opportunity to try out exoskeletons with different functions and for different parts of the body for themselves. The report on findings and recommendations for future use were of great interest.

Completion of the Exo@Work research project

The content of the research project "Exo@Work - Evaluation of exoskeletal systems in the world of work" came to an end at the end of 2021. The project started in October 2018, was commissioned by the German Social Accident Insurance Institution for the trade and goods logistics sector (BGHW) and was carried out jointly with the Institute for Occupational Safety and Health (IFA) of the German Social Accident Insurance (DGUV). The Chair of Production Engineering was assigned the role of lead in the project. In terms of acceptance and usability, the project focussed on evaluating the support effects of exoskeletons. The central result of the project is a guideline for commercial companies, which is intended to provide recommendations for the implementation and evaluation of exoskeletons in use. The results were also presented by Lennart Ralfs and Niclas Hoffmann at the final Exo@Work project support group meeting on 5 May 2022. The guidelines will soon be published in the BGHW's occupational health and safety compendium and will be available for download there for interested parties.

Participation and presentation at the 4th exchange of experience "Use of exoskeletons in the world of work"

As part of the 4th exchange of experience "Use of exoskeletons in the world of work", which was organised by the Berufsgenossenschaft Handel und Warenlogistik (BGHW) on 4 May 2022 in Mannheim, participants from science and practice (including manufacturers, developers and users of exoskeletons) came together to discuss the current status quo of exoskeletons in the world of work and to exchange experiences with each other. Niclas Hoffmann and Lennart Ralfs took part on behalf of the Chair of Production Engineering. As part of the programme, Lennart Ralfs presented the key results of the Exo@Work research project on behalf of the project team from the University of Innsbruck. In the subsequent discussion, possible future directions and focal points in relation to exoskeletons were also discussed in the plenary session.

Univ.-Prof. Dr.-Ing. Robert Weidner elected 1st Vice President of the ÖWGP - Austrian Scientific Society for Production Engineering

The Austrian Scientific Society for Production Engineering (ÖWGP) elected Prof Dr Robert Weidner as its new 1st Vice President at its Annual General Meeting in February. The ÖWGP was founded on 17 June 2013 based on the model of the German "Wissenschaftliche Gesellschaft für Produktionstechnik (WGP)". It sees itself as an association of professors from Austrian universities with the aim of promoting science and research-led teaching in the field of production engineering. The ÖWGP also supports co-operation between scientific institutes, social and political associations and industry. You can find more information at Science Information Service or University of Innsbruck.

Staff growth at the professorship

We would like to welcome Katharina Schmermbeck, MSc as a new member of our team. As a PhD student in Technical Sciences, her research will include a context-dependent framework for the development and integration of adaptive assistance systems in industrial applications.

Participation of the team from the Chair of Production Engineering in the Tyrol Cycles campaign

The team at the Chair of Production Engineering is taking part in the Tyrol Cycles 2022 campaign. This involves collecting kilometres by bike both at work and at home in the interests of health.

Welcoming Mr Stefan Schoch to the professorship

We would like to welcome Mr Stefan Schoch, BSc as an Erasmus student and an extension of our team as a student employee. He has completed his Bachelor's degree in Mechanical Engineering at Munich University of Applied Sciences and is currently in the final stages of his Master's programme. He is writing his Master's thesis with us as part of the Erasmus programme in the field of "Development of an active exoskeleton for heavy-duty applications". He is also a student assistant at the professorship and supports our research activities.

Participants wanted for exoskeleton study

If you are interested in participating in the study, please find information at here.

Lecture and panel discussion at the 37th International A+A Congress

The 37th International A+A Congress for Occupational Safety and Health 2021 took place in Düsseldorf from 26 to 29 October 2021. As part of the Trend Forum Exoskeletons, Lennart Ralfs presented current research results under the lecture title "Einflüsse industrieller Exoskekeletletten auf die physische und kognitive Beanspruchung von Mitarbeiter*innen / Influences of inudstral exoskeletons on the physical and cognitive strain on employees". The topic was then discussed further in a panel discussion with the other three speakers.

Inaugural lecture "Workplace of the future: Holistic approach to individual and context-dependent support"

Univ.-Prof. Dr.-Ing. Robert Weidner

on

Monday, 11 November 2019, 17:00 hrs

at the

Faculty of Engineering Sciences,

Large Lecture Hall, Technikerstrasse 13,

6020 Innsbruck

Welcome by the Rector

Univ.-Prof. Dr Dr h. c. mult. Tilmann Märk

Welcome by the Dean of the Faculty of Engineering Sciences

Dipl.-Ing. Dr. techn. Günter Hofstetter

Registration is requested: tamara.kern@uibk.ac.at

Lecture on exoskeletons at WearRAcon Europe 2021

WearRAcon Europe 2021 took place from 5-7 October 2021, which was held virtually due to the pandemic situation. The conference provided an insight into the European aspects of industrial exoskeleton technologies and their assessment methods. In the session "Benchmarking & Assessment II", Lennart Ralfs presented research results from the Chair of Production Engineering under the lecture title "Evaluation of Industrial Exoskeletons - Methodology and Exemplary Results".

Contribution to the symposium "Safety and health in goods logistics"

From 13-15 September 2021, the Berufsgenossenschaft Handel und Warenlogistik (BGHW) organised the symposium "Safety and Health in Goods Logistics" at its academy in Dresden/Germany. Matthias Höfer and Lennart Ralfs represented the Chair of Production Engineering as invited participants. On the one hand, they looked after an exhibitor stand with various exoskeletons and test stations on the marketplace and advised interested safety specialists from industrial companies. Secondly, they presented the current research results of the Exo@Work project as part of the forum.

Admission as a member of the Austrian Scientific Society for Production Engineering (ÖWGP)

Robert Weidner was accepted as a member of the Austrian Scientific Society for Production Engineering at the ÖWGP summer retreat on 27/28 August 2021 at Grundlsee. Further information on the ÖWGP can be found at www.oewgp.at.

Presentation of two research papers at the 6th colloquium of the Scientific Society for Assembly, Handling and Industrial Robotics (MHI)

On 10/11 June 2021, the 6th Technical Colloquium of the Scientific Society for Assembly, Handling and Industrial Robotics (MHI) took place in virtual form due to the current coronavirus pandemic. Samet Ersoysal and Lennart Ralfs presented two scientific papers at the two-day conference. One paper addressed the development of design concepts and control principles for a modular elbow exoskeleton, including the construction of a prototype. Another paper focussed on the development of a decision-support matrix for the selection of suitable exoskeletons for industrial application scenarios.

Admission as a member of the Scientific Society for Assembly, Handling and Industrial Robotics (MHI)

At the spring meeting of the Scientific Society for Assembly, Handling and Industrial Robotics on 9/10 June 2021 in Hanover/Germany, Prof. Dr Robert Weidner was accepted as a member of MHI e.V., a network of leading university professors from German-speaking countries. In terms of expertise, the focus is on fundamental and application-orientated research into future-oriented topics in assembly, handling and industrial robotics. Further information on the Scientific Society for Assembly, Handling and Industrial Robotics (MHI e.V.) can be found at www.wgmhi.com.

Journal Paper for Applied Sciences accepted

An active exosuit was developed for patients with weak foot dorsiflexion, which supports dorsiflexion in the ankle joint depending on the gait phase and is therefore intended to reduce compensatory movements and the risk of falls. The paper describes the system design and a pilot study in which healthy test subjects were used to rule out any movement restrictions caused by the system when walking. Due to non-significant differences in walking with and without the exosuit, the effects on gait behaviour in patients can be investigated in a next step.

Publication details: T. Schubert, B. Wollesen, R. Weidner: Development and Preliminary Evaluation of a Lower Body Exosuit to Support Ankle Dorsiflexion. Applied Sciences 11 (11), 2021.

Staff growth at the professorship

We would like to welcome Mr Oliver Simon Ott, MSc as a new member of our team. As a PhD student in technical sciences, he is focusing on possible applications of artificial intelligence methods for the structural and control optimisation of exoskeletons.

Presentations at the 67th Spring Congress of the Society for Human Factors

On Thursday, 4 March 2021, the Chair of Production Engineering presented two research papers at the 67th Spring Congress of the Society for Industrial Engineering in Bochum. One of the papers dealt with the design and multidimensional evaluation of exoskeletal interfaces. The other paper presented the results of a study on the acceptance and usability of exoskeletons for back support, which was carried out at eight DB Schenker sites as part of the exo@work research project.

New member of staff at the professorship

We would like to welcome Mrs Regina Schönherr, Dipl.-Ing., BSc as a new member of our team. As a PhD student of technical sciences, she is focussing on methods of artificial intelligence for the control and regulation of active exoskeletons.

New appointment to the institute secretariat

Ms Magdalena Gredler joined the institute secretariat on 4 January 2021. We warmly welcome her to the Chair of Production Engineering. From now on, Ms Magdalena Gredler will be responsible for organisational tasks and topics related to teaching.

Lecture as part of the European Researchers' Night on 27 November 2020

In a 45-minute presentation entitled "Exoskeletons as a technical means of supporting people", the Chair of Production Engineering gave an insight into the main topics of the research group. Both general basics in the form of an introductory presentation and practical insights into the laboratory and the available equipment were given. The lecture was streamed via the internet and met with great interest.

Acknowledgements: Funding of the research project "Simulative Evaluation of Exoskeletons" by Swarovski KG

On Tuesday, 9 July 2019, Mr Hoffmann accepted the research funding certificates from the Daniel Swarovski KG campaign on behalf of the Chair of Production Engineering. The research project will focus on the evaluation of exoskeletons based on simulation software. Many thanks to Swarovski KG.

Support for the IG-Metall conference on the digitalisation of the construction industry

On Tuesday, 2 April 2019, the Chair of Production Engineering supported a symposium organised by "IG Metall" in Frankfurt am Main, which dealt with the effects of digitalisation on skilled work in the construction industry and construction-related trades. In a short keynote speech, Mr Hoffmann presented exoskeletons, their many variations and some of the advantages that could result from their use in the construction industry.

The conference participants also had the opportunity to try out two different exoskeletons in practice. The professorship is looking forward to further collaboration with "IG Metall".

Establishment of the Chair of Production Engineering

After Mr Robert Weidner took up his post at the LFUI in August 2018, the Chair of Production Engineering will be established. The focus in research and teaching will be on the workplace of the future.

In recent years, Mr Weidner has headed the interdisciplinary junior research group smartASSIST, which was funded by the Federal Ministry of Education and Research in Germany. With his research group at the Helmut Schmidt University/University of the Federal Armed Forces Hamburg, he researches methods for technology development and evaluation, concepts for human-machine interaction and technologies to support manual activities (exoskeletons for various areas of application and body regions). This research will also be his focus at the LFUI.

Transdisciplinary conference "Technical support systems that people really want" on 11 and 12 December 2018

On 11 and 12 December 2018, the third transdisciplinary conference "Technical support systems that people really want" will take place in Hamburg at Helmut Schmidt University. This event is organised and hosted by Prof. Weidner and his team. The conference is aimed at scientists and students from various disciplines as well as interested stakeholders from industry, politics and associations. Work on requirements, approaches, systems and development processes will be presented and discussed together.

Further information on the conference will follow shortly on the conference website at www.smartASSIST.info. If you have any questions, please contact the conference team at smartASSIST@hsu-hh.de.

exoATwork - Start of training sessions for Austrian companies on the topic of exoskeletons for manual workstations

The Innovation Camp M Exoskeletons for Manual Workplaces (exoATwork) project, funded by the FFG, supports nine small and medium-sized enterprises and 17 large companies from various sectors in building up expertise in analysing manual work activities and in selecting and implementing support technologies in existing work processes.

The first training units will start on 10 and 11 January 2023. The project is divided into four modules and will run until September 2024. It comprises a total of 23 training units and concludes with an accompanied introduction of technical support systems in selected participating companies.

The practice-orientated training is designed to enable participants to

- better analyse their work processes and identify support requirements

- organise their workplaces more ergonomically through the use of technical support systems and

- assess the individual and operational added value of the measures.

| Name | Organisation | Name | Organisation |

|---|---|---|---|

| Sebastian Schlund | TU Vienna | Lisa-Marie Faller | FH Carinthia |

| Philipp Hold | Fraunhofer Austria | Mathias Brandstötter | FH Carinthia |

| Martina Mara | JKU Linz | Michael Rathmair | Joanneum Research |

| Sandra Siedl | JKU Linz | Michael Wichtl | ÖAE |

| Georg Göbel | Innsbruck Medical University | Peter Kuhlang | MTM |

| Matthias Kettemann | UIBK | Martin Benter | MTM |

| Peter Federolf | UIBK | Athanasios Karafillidis | YMCA Kassel |

| Robert Eberle | UIBK | Verena Nitsch | RWTH Aachen |

| Norbert Lechner | AUVA | Alexander Mertens | RWTH Aachen |

Participating companies: ADA Möbelfabrik, AEROVISION Drone Support, awb Schraubtechnik, Durst Austria, Fleischwaren Berger, Gebrüder Weiss, Griffnerhaus, GW St. Pölten Integrative Betriebe, Haas Fertigbau, Hartl Haus Holzindustrie, Haubis, Hella Sonnen- und Wetterschutztechnik, INNIO, Julius Blum, LSA Luft-Systeme Althuber, Magna Steyr, Mahle Filtersysteme, Mark Metallwarenfabrik, Morandell, Peneder Bau-Elemente, Pöltl KG, Riedle Installationen, TB Feistritzer, TPA KKS, TÜV AUSTRIA, Weitzer Wood Solutions, Wild GmbH.

Further information can be found at Website Innovation Camp Exoskeletons for manual workstations (exoATwork).

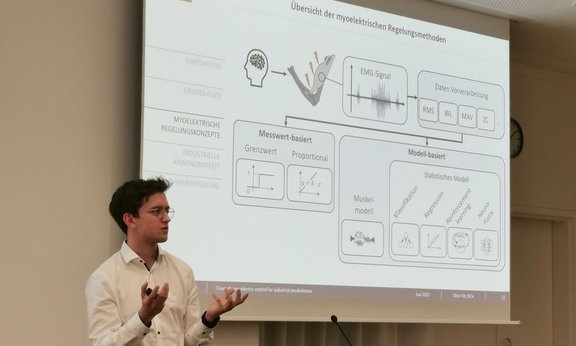

Best Paper Award for Oliver Ott at the WG-MHI Colloquium 2023

We are pleased to announce that Oliver Ott has received the coveted Best Paper Award at the WG-MHI Technical Colloquium 2023 for his paper "Towards myoelectric control for industrial exoskeletons". This award not only honours his work, but also underlines the importance of his research contribution to the future of human-machine interaction.

Oliver Ott would like to express his sincere thanks for the great honour of receiving this prestigious award. The paper "Towards myoelectric control for industrial exoskeletons" presented an approach to myoelectric control of industrial exoskeletons. This research opens up exciting possibilities for seamless interaction between humans and machines in industrial environments.

Being recognised by the Best Paper Award encourages Oliver Ott and our research team to pursue the presented approach and make new advances in human-machine interaction. The support and appreciation within the community are of outstanding importance and spur us on to continue our efforts to design advanced human-machine interaction.

We would therefore like to thank Scientific Society for Assembly, Handling and Industrial Robotics - MHI e.V. for providing a platform for the exchange of pioneering ideas and research results. This award encourages us to continue our efforts to design advanced human-machine interaction and to shape the future of the world of work.

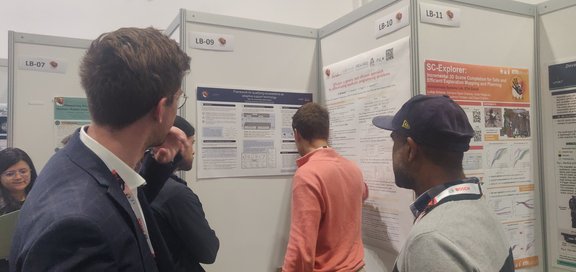

Shaping the future: Research presentations at the WG-MHI Colloquium 2023

Our recent participation in the specialist colloquium of Scientific Society for Assembly, Handling and Industrial Robotics - MHI e.V. on 22 - 23 June 2023 in Chemnitz was an inspiring experience. We are grateful for the opportunity to present our current research results at this important forum.

Two of our researchers participated in the topic of human-machine interaction and machine vision:

Samet Ersoysal presented, "Development and Testing of an Elbow Exoskeleton Prototype with Pneumatic Actuation for Industrial Tasks." His innovative approach represents an extension of our Lucy shoulder exoskeleton to include the elbow and thus provides an important basis for future research into upper limb support.

Oliver Ott presented: "Towards myoelectric control for industrial exoskeletons." His approach to integrating myoelectric control into industrial exoskeletons shows a way forward for increased human-machine interaction in challenging environments.

The discussions and exchange of knowledge at the specialist colloquium were stimulating and opened up new horizons for the design of tomorrow's technology. We would like to thank the organisers and the host, the Fraunhofer Institute for Machine Tools and Forming Technology IWU, for this valuable platform and look forward to continuing to explore the frontiers of innovation in human-machine interaction.

Exploring the diversity of assistive technologies: opportunities and challenges

Assistance technologies have become an indispensable part of our lives in modern society. The recently held basic module 2 of the exoATwork innovation camp on 13 and 14 June in Innsbruck and on 21 June in Vienna offered participants the opportunity to delve deeper into the world of assistance technology and get to know different forms. The focus was on motion assistance, perception assistance and decision assistance.

Motion assistance: Industrial robots, lifting aids and exoskeletons are examples of motion assistance technologies that are used in various areas. The advantages of increased efficiency and accuracy were discussed, but also the potential disadvantages such as high acquisition costs and technical dependency.

Perceptual assistance: Motion tracking, eye tracking, smart watches and smart textiles enhance our sensory perception and enable precise data collection. The participants explored the benefits of these technologies, including improved interactions and personalised experiences. At the same time, concerns about data protection and surveillance that may accompany the increased use of these technologies were discussed.

Decision support: Virtual reality, augmented reality and mixed reality offer fascinating opportunities to augment reality and support decision-making processes. The participants explored the advantages of these technologies, such as immersive learning environments and realistic simulations. Potential disadvantages such as disorienting effects and the need for appropriate familiarisation were also addressed.

The module ended with an exciting hands-on experience where participants were able to experience different forms of virtual, augmented and mixed reality on their own bodies. This practical application helped the participants to develop a deeper understanding of the potential and challenges of assistive technologies.

Overall, the module gave the participants a comprehensive insight into the world of assistance technologies and helped them to better understand the advantages and disadvantages of different technologies.

Einblick in unterschiedliche Assistenztechnologien (Vortragender: Oliver Ott, M.Sc.)

Smarter Lives meets INNKlusion

Our new INNKlusion project was presented as part of a short technical presentation by Oliver Ott at Smarter Lives 2023 (https://www.smarter-lives.eu/) on 24 May 2023. INNKlusion is our new project, which we implemented as part of the CAD internship with bachelor students of mechatronics. The students developed new everyday technologies together with people with disabilities and other experts. We are delighted with the great interest and positive feedback from the participants from the Ambient Assisted Living (AAL) environment.

Presentation at ICRA 2023

Between 29 May and 2 June, the world's experts in the field of robotics and automation gathered at the 40th IEEE International Conference on Robotics and Automation (ICRA) in London to exchange the latest findings and research results. As part of the discourse, Oliver Ott presented our recently published framework for the qualification of exoskeletons as adaptive support technology (the publication can be found at here).

The research results were met with great approval and further exciting questions for further research were derived from the discourse. We are delighted about the support and encouragement for our research from the international community and are looking forward to the further results with a view to the next conferences.

Status meeting in the A2P project at Siemens Technology

As part of the A2P project, the next face-to-face meeting took place on 31 May 2023. This time, the project team met at Siemens Technology's DigiLab in Vienna. The focus of the meeting was on discussing the project results to date as well as the upcoming priorities and work content. For example, a classification approach for industrial activities and the basic structure of a framework for the industrialisation of adaptive assistance systems have been developed and several data sets have been recorded as a basis for further project work. Overall, the project team's assessment of the first year of the project was positive.

Spring Conference of the Scientific Society for Assembly, Handling and Industrial Robotics (WGMHI)

The spring conference of the Scientific Society for Assembly, Handling and Industrial Robotics took place from 8-10 May 2023 at the Production Technology Centre (PTZ) of TU Berlin. In addition to the professors, the member institutes also sent a senior engineer, head of department or research assistant for the first time. Robert Weidner and Lennart Ralfs represented the Chair of Production Engineering at the University of Innsbruck. The agenda for the joint discussion included strategic topics such as the future direction and key topics of the WGMHI as well as further potential for structural networking of the member institutes.

Hands-on ergonomics in the exoATwork module "Practical implementation project"

The participants of the Exoskeletons for Manual Workstations innovation camp met on 26 and 27 April and 24 and 25 May in the movement laboratory of the Chair of Production Engineering at the University of Innsbruck to learn about various ergonomics and workplace assessment methods in theory and practice in a two-day seminar.

In addition to an introduction to the most common overload injuries and an analysis of the biomechanical risk factors, various assessment and measurement methods were presented and applied in order to quantify the loads that occur. Two different work processes were simulated in the laboratory with the focus on modelling a wide range of different manual activities. While two members of our working group "worked hard", the seminar participants were able to literally look under the workers' skin and observe the stresses that occur during work using various sensor and camera-based measurement systems.

As experts for the work processes in the respective companies, the participants will be presented with a tool of assessment methods and procedures. Depending on the boundary conditions and circumstances, they will be able to decide which methods are most suitable in the respective context in order to be able to assess the stresses at the workplaces and (if necessary) carry out the optimisation based on this - which they will also deal with intensively in the following units of exoATwork.

Further information on the FFG-funded exoATwork project can be found at Website Innovation Camp Exoskeletons for manual workstations (exoATwork).

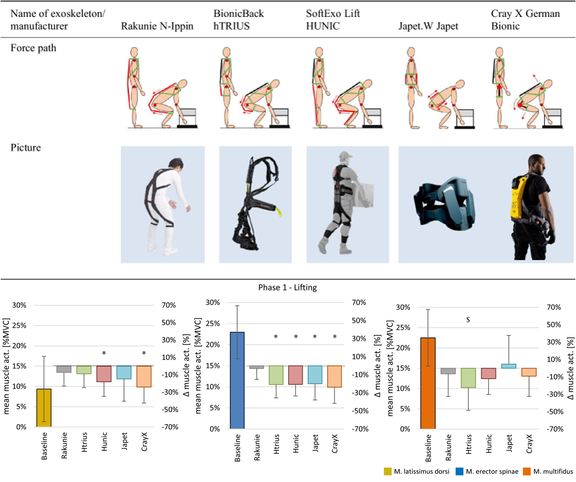

"Exo, watch my back!"

What influence do the different functional mechanisms of industrial exoskeletons have on the biomechanics of the user?

On 19 April, the scientific article Effects of back-support exoskeletons with different functional mechanisms on trunk muscle activity and kinematics was published in the journal Wearable Technologies by Cambridge University Press. The article deals with the biomechanical effects of wearing exoskeletons and analyses in particular the influence of the different active and functional mechanisms of the technical support systems. Five commercially available, back-supporting exoskeletons were tested on 12 test subjects (3 female, 9 male) during a lifting and carrying activity.

Four of the five exoskeletons tested produced significant changes in the activity of the back muscles. More detailed analyses of the force flow and functional principle of the exoskeletons provide initial explanations to better understand the different results and their effects on users.

The figures opposite summarise the results of the muscle activity analysis for lifting and putting down the weight. In some cases, movement restrictions (particularly in the hip flexion) were also observed as a result of wearing the exoskeletons during the activity.

A one-dimensional assessment of exoskeletons does not do justice to the complex problem of overexertion damage and injuries. To reduce the risk of work-related musculoskeletal disorders, a better understanding of the comprehensive biomechanical effects of exoskeletons and their mechanisms of action is required, and our paper is intended to provide a step in this direction.

You can find the publication under the following link:

https://doi.org/10.1017/wtc.2023.5

Status meeting in the A2P project at Infineon Technologies

On 12 December 2022, the first project meeting after the kick-off of the FFG-funded research project "A2P (Assist to Produce) - Framework for the industrialisation of adaptive assistance systems in production" took place at Infineon Technologies in Villach. The A2P (Assist to Produce) research project aims to create a scalable and application-independent implementation framework as a prerequisite for the broad industrialisation of adaptive assistance systems such as cobots, augmented reality and exoskeletons in the production context. The meeting focussed on discussing the use cases of the application partners involved in the project and approaches for creating an overarching framework.