Environmentally friendly production and extraction of PHB bioplastics

Funding: Tyrolean innovation funding

Funding period: 10/2021 - 12/2023

Project partner:

- University of Innsbruck, Institute for Infrastructure, AB Environmental Technology: Investigations into PHB production on a laboratory scale

- BioTreat GmbH: Pilot-scale trials

- ALPEX Technologies GmbH: Testing materials injection

- troi.composite components: Testing materials in 3D printing

Project description:

The production of plastics is currently largely petrochemical, although the demand for biologically producible and degradable polymers is growing. Bioplastics currently account for around 1% of the total amount of plastics produced worldwide [1]. Plastics made from polyhydroxyalkanoates (PHAs) in particular, which can be produced and composted entirely via biological processes compared to other types of "bioplastics" such as polylactides (PLA), offer the prospect of new types of plastic-based materials. Polyhydroxyalkanoates are produced by a variety of naturally occurring bacteria. PHB (polyhydroxybutyrate) is the most commonly produced representative of polyhydroxyalkanoates. PHB has comparable technical properties to polyethylene (PE) and polypropylene (PP) and can be processed in common manufacturing processes such as extrusion and injection moulding. Two main areas are addressed in this project:

1: Nutrient supply for the bacteria: A major challenge for the ecological meaningfulness and economic efficiency is the utilisation of wastewater or residual materials for nutrient supply of the PHB-producing microorganisms. Various food companies in Tyrol are currently considering how the wastewater produced could be utilised to the highest possible quality in terms of the circular economy. Specifically, successful preliminary tests have already been carried out to concentrate such wastewater for further utilisation. Utilising these concentrates for PHB production would be a very promising approach.

2: Separation of PHB: In addition to the use of wastewater as a substrate for PHB production, the focus is on cell fractionation of MO and extraction of PHBs while minimising chemical or environmentally harmful purification methods. In this project, cell disruption is to be carried out largely by thermal and mechanical fractionation in order to enable further processing of the resulting material (PHBs with little residual cell material). This approach is not found in the current technical literature.

The method to be developed is intended to make the production of bioplastics simpler, cheaper and more environmentally friendly. The influence of the remaining cell residues on the material properties is to be investigated, with initial tests holding out the prospect of improved and faster biodegradability.

The motivation for this project arose from the study of industrial wastewater from the food industry in Tyrol. This wastewater contains various high-value carbon compounds, which are currently degraded in wastewater treatment plants at a high energy cost. The aim is to utilise these substances as efficiently as possible.

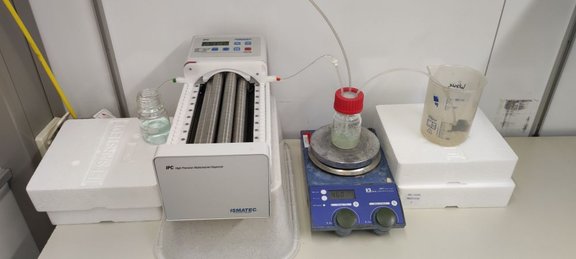

Einfache, kontinuierlich betriebene Reaktoren zur Anreicherung/Selektion einer PHB produzierenden Mischkultur

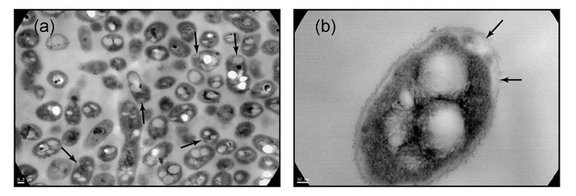

Das PHB produzierende Bakterium Cupriavidus necator mit PHB Granulen in den Zellen

Bioreaktor zur Kultivierung der PHB produzierenden Mischkultur

Contact:

Dr Christian Ebner

Technikerstrasse 13

6020 Innsbruck