Ongoing projects

EMPOWER - Empowered Workers Collaborating with Cognified Machines

Advances in Artificial Intelligence (AI) in general, and Machine Learning (ML) in particular, have meant that human-machine collaboration is constantly evolving our expectations of what machines can do with the help of AI, but also of what humans can do with the physical and mechanical assistance of AI-driven machines.

This project (EMPOWER) is driven by the conviction that the performance of human-machine collaboration is based on the convergence of (i) the core intellectual capabilities of humans and (ii) the power and precision of machines. EMPOWER strives for a performance-efficient interweaving of human and machine capabilities by (i) integrating advanced AI technology into industrial machines (cognification), while (ii) at the same time enhancing the physical strength of humans through body-worn support systems such as exoskeletons (empowerment).

EMPOWER (i) is based on multimodal, multi-sensor perception of work situations in human-machine collaboration, (ii) attempts to recognise current work tasks based on manipulation activities and the worker's skill level, (iii) seeks an understanding of the workflow to predict upcoming work steps, and (iv) adjusts control settings to meet the mechanical requirements of future work steps.

Through this, EMPOWER introduces embedded AI technologies to predict the worker's intent in real-time and proactively adjust the operational and mechanical configurations of body-worn robots and exoskeletons. "Predictive Adjustment" is seen as the next generation of exoskeleton control mechanisms, heralding a new era of body-worn robotics that adapt to work processes, individual body anthropometry, female/male users, heterogeneous ability and experience levels, impairments, etc., evolving today's passive support systems into active exoskeletons.

EMPOWER will demonstrate the qualities of proactive exoskeletons using use cases from the field of industrial work (steel processing, construction, logistics, assembly) in the factories of well-known Austrian companies (Alfred Wagner Stahl, Gebrüder Weiss), exoskeleton and control system providers (exoIQ, ADRESYS), innovators in the field of sustainable energy (OPEXZERO, photovoltaics) and providers of intelligent textiles (TEXIBLE). Upper body exoskeleton prototypes (back and shoulder) and reference systems will be designed and implemented to empirically demonstrate the benefits of active exoskeletons.

The innovation of proactive exoskeletons is a significant step towards energy efficiency due to low power consumption. The integrated task and intention prediction enables energy savings for exoskeletons and collaborative machines through usage-based activation.

More information on the project can be found at FFG projects.

Duration and consortium

01.04.2024 - 31.03.2027

Johannes Kepler University Linz - Institute for Pervasive Computing

University of Innsbruck - Department of Mechatronics, Chair of Production Engineering

Alfred Wagner Stahl-Technik & Zuschnitt GmbH

Adaptive Regelsysteme Gesellschaft m.b.H.

Gebrüder Weiss Gesellschaft m.b.H.

Assist to Produce - A2P

Framework for the industrialisation of adaptive assistance systems in production

Project objectives and approach

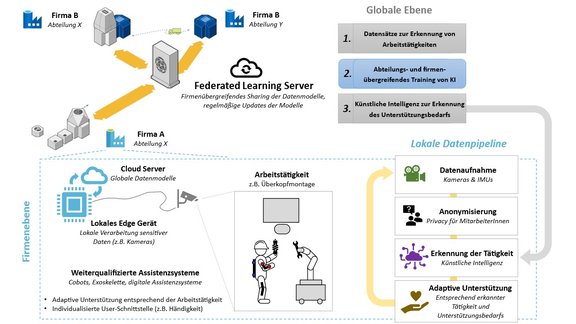

Adaptive assistance technologies for industrial applications have demonstrably positive effects on productivity, error rates and the physical and mental strain on employees. Despite these advantages, their penetration in industry has not yet progressed beyond prototype use in some areas. The reasons for this are the high development costs, costly customisation, inefficient human-machine interaction and the need for data protection-compliant and secure data management. A2P (Assist to Produce) builds on these challenges and addresses the development of a framework for adaptive physical and digital assistance systems through activity recognition. Open data sets for recognising industrial activities using neural networks and identifying work steps with a potential need for assistance serve as the basis. Furthermore, the project creates the basis for sustainable privacy protection in production systems by using existing techniques for anonymising private or sensitive data and for secure, cross-company training of AI using federated learning in industrial areas.

You can find more information about the project at FFG projects.

Duration and consortium

01.05.2022 - 31.10.2025

TU Vienna, Institute of Management Sciences, Human-Machine Interaction Research Grouphttps://www.tuwien.at/mwbw/im/mmi

Infineon Technologies Austria AG https://www.infineon.com/cms/austria/de/

MICADO AUTOMATION GmbH www.micado-automation.at

Siemens Aktiengesellschaft Austria https://new.siemens.com/at/de/unternehmen/themenfelder/innovation-labs/digilab-wien.html

Siemens Mobility Austria GmbH https://www.mobility.siemens.com/at/de.html

University of Innsbruck, Department of Mechatronics, Chair of Production Engineering https://www.uibk.ac.at/mechatronik/fertigungstechnik/

Former projects

Exo@Work - Evaluation of exoskeletal systems in the world of work

The Exo@Work project aims to develop a practical guide for the evaluation of exoskeletons in the working environment. The basis for this is a comprehensive analysis, on the basis of which a methodological procedure for the systematic evaluation of corresponding systems is being developed. This approach will be validated in both laboratory and field studies with selected exoskeletons. These systems are selected in such a way that different basic concepts are mapped, for example with regard to the morphological structure (rigid or textile-based) and the actuators (active or passive). This is to ensure that the guideline takes into account the main variants and enables a differentiated assessment.

First of all, key basic principles are recorded and systematised: the current state of research, typical activity profiles and findings on preventive effects, health risks and stresses. Based on this, a catalogue of methods will be developed, which will be reviewed and further developed with the help of laboratory and practical tests with exemplary exoskeletons. At the same time, overarching issues such as user acceptance and usability are analysed. Finally, a multi-criteria evaluation procedure is used to identify the key properties that are decisive for the assessment of exoskeletons. Exemplary fields of application from industrial production, logistics and retail will be used for testing. All results are incorporated into a guideline that offers recommendations for evaluation.

The project organiser and client of Exo@Work is the Berufsgenossenschaft Handel und Warenlogistik (BGHW). The project is being carried out in cooperation with the Institute for Occupational Safety and Health (IFA) of the German Social Accident Insurance (DGUV).

Summarised scientific publication: https://www.sciencedirect.com/science/article/pii/S0169814123000860?via%3Dihub

Developed guideline (in the BGHW's compendium on occupational health and safety): https://kompendium.bghw.de/bghw/xhtml/document.jsf?alias=bghw_fors_b12fblee_GR1_&event=navigation&redirect2alias=bghw_fors_b12fblee_GR1_

Website project partner IFA: https://www.dguv.de/ifa/forschung/projektverzeichnis/ifa4235.jsp

exoATwork - exoskeletons for manual workstations

Manufacturing companies are facing various challenges. Demographic change, longer working lives, a shortage of skilled workers and product customisation are increasing costs. This is why the physical support of employees through exoskeletons is becoming increasingly important. Our offer is aimed at all companies that want to prepare their production for the demands of tomorrow by

a. better understanding their own work processes, analysing them and their needs

b. ergonomically optimising workstations with exoskeletons Design and optimisation

c. Achieving the support of the workforce Understanding and added value

The aim of the exoATwork innovation camp is to provide 66 employees from 9 SMEs and 19 JVs from all manufacturing sectors with research-based knowledge and concrete recommendations for the ergonomic and sustainable design of manual workstations through lectures, workshops and practical case studies.

You can find more information about the project at FFG projects.

ExoExpert - Knowledge-based planning for the use of exoskeletons

Motivation

Co-operation between humans and technology, for example in the world of work, has intensified in recent years. As an approach to supporting human labour, exoskeletons have increasingly emerged as a suitable support technology in industry. Depending on the production scenario, exoskeletons are suitable for supporting workers by either facilitating or supplementing movements or stabilising postures. However, supporting methods or tools for the simulation-based selection and adaptation of exoskeletons only exist for individual aspects to date.

Objective

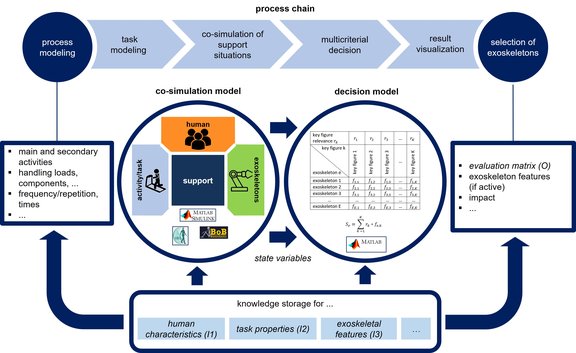

Due to a lack of knowledge and models for the detailed and holistic simulation of exoskeletons in manual production scenarios, for example with regard to dynamic and kinematic aspects, there is uncertainty about their targeted use and supporting effect on the human body. To remedy this, ExoExpert aims to develop a novel planning method including a simulation model to provide decision support for the identification of exoskeletons for manual production processes and the adaptation of system behaviour. Ultimately, the project aims to support occupational scientists, ergonomists and engineers in appropriately evaluating, selecting and adapting exoskeletons for industrial application scenarios prior to system implementation. The aim is to

- develop a system for describing heterogeneous exoskeletons,

- set up a co-simulation model for multi-criteria evaluation and

- derive a decision model for the context-adapted selection of an exoskeleton.

Approach

The knowledge- and simulation-based method consists of four main building blocks. Based on the analysis of properties and state-of-the-art methods, a (1) evaluation system for heterogeneous exoskeletons is designed. This system serves as the basis for the development of a (2) co-simulation model, which is composed of the modelling and simulation of (a) process-related and (b) technical and biomechanical parameters. A (3) decision model operationalises the co-simulation results with regard to the context-adapted selection of exoskeletons. The final step provides for (4) practical validation and optimisation of the developed method using exoskeleton demonstrators before the method is generalised.

Consortium

The ExoExpert project is a basic research project in which the Chair of Production Systems at the Ruhr University Bochum (RUB), Univ.-Prof. Dr.-Ing. Bernd Kuhlenkötter and the Chair of Production Engineering at the University of Innsbruck (UIBK), Univ.-Prof. Dr.-Ing. Robert Weidner are involved. ExoExpert is funded by the German Research Foundation (DFG) and the Austrian Science Fund (FWF).