Univ.-Prof. Dr. Oliver I. Strube

Chemicals and Materials Engineering

The focus of our research projects is the linking of biological motifs with material technology applications and modern process engineering.

Within this scope, we use a variety of raw materials provided by nature to create innovative materials. Many of our projects also follow the principle of biomimetics. This describes abstraction of natural archetypes to apply them to a technical problem. This has led, for example, to squid-inspired glass fiber composites and the idea of a snakeskin-inspired circular economy for painted surfaces.

In addition to the industrial applicability of the materials, we attach great importance to an in-depth understanding of the underlying processes and structures. To this end, we use e.g. high-resolution microscopy methods, to look deep into the structure and chemistry of our materials.

This focus includes bio-based raw materials and biomimetic structures. The production of biogenic, functional materials is preferably carried out from waste materials such as chitin or terpenes. We always attach great importance to a functional advantage of the bio-based systems. Numerous micro- and nanoscale structural elements in our materials are also inspired by nature.

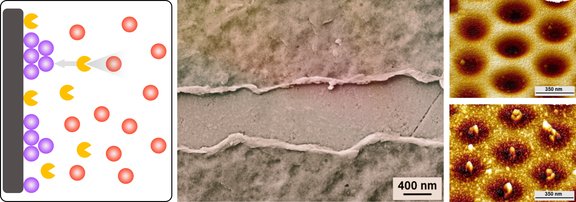

In addition, we are researching new materials and coating processes for applications in the medical field. Specific research topics include enzyme-mediated nanostructuring of surfaces, materials made from melanin and enzyme-free hydrogels made from the blood protein fibrinogen.

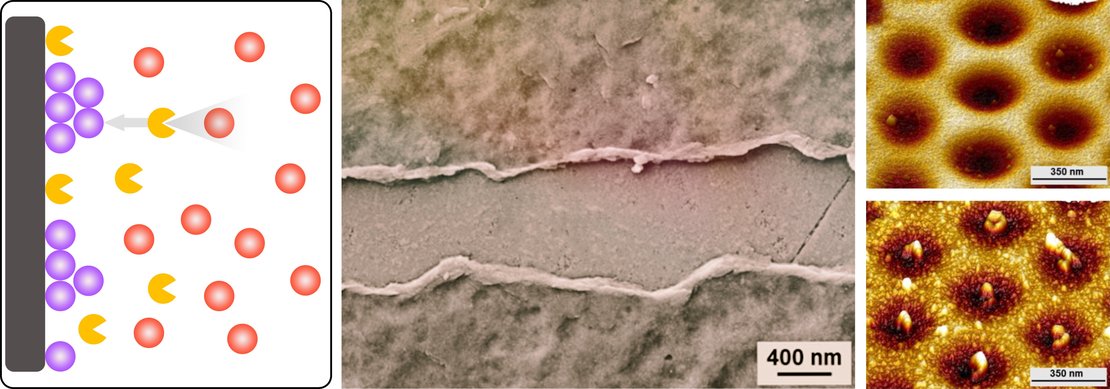

SEM images and photographs of fibrous fibrinogen hydrogels (left) and the resulting lyophilized aerogels (right).

Lots of our research projects are directly related to coatings of all kinds. We look at the system “paint” wholistically, i.e. microscopically, macroscopically and in terms of process technology. The aim is usually to integrate a specific functionality. Research into innovative application processes is also part of our expertise. For example, we are researching the coating of reinforcement fibers directly in the spinning process, moisture-adaptive coatings for interior insulation systems, or palladium coatings for the selective separation of hydrogen.

Example of a detached wood coating. The coating developed in our working group enables a residue-free debonding-on-demand from its substrate.

Concept of wet-chemical deposition of palladium to create highly selective membranes for H2 separation (left) and a SEM image of the deposited Pd particles.

Schematic representation of the enzyme-mediated addressing to create nanostructures (left) and examples of protein coatings (middle) and structures (right).

In the spirit of a genuine circular economy, we are particularly concerned with the targeted delamination of coatings and the separation of liquid residual streams from the paint industry. These are extremely relevant topics for the coatings industry for both economic and regulatory reasons. Here we develop procedures and process technologies with which coatings can be completely removed from the substrate after their service life. We also develop process engineering systems to re-separate water-based paints into their basic components.

Concept of the recycling of waterborne coatings and its application in practice.